Actor e phahameng ea khatello (matla a khoheli a phahameng a khatello) e emela popontšo e kholo ea ho sebelisa theknoloji ea magnete drive ho lisebelisoa tsa karabelo. E rarolla mathata a ho lutla a ho koala ha shaft e amanang le litiiso tsa setso tsa ho paka le litiiso tsa mochini, ho netefatsa hore ha ho dutla le ho silafala. Sena se etsa hore e be sesebelisoa se loketseng bakeng sa ho tsamaisa lik'hemik'hale tlas'a maemo a phahameng a mocheso le khatello e phahameng, haholo-holo bakeng sa lintho tse tukang, tse qhomang le tse chefo, moo melemo ea eona e bonahalang le ho feta.

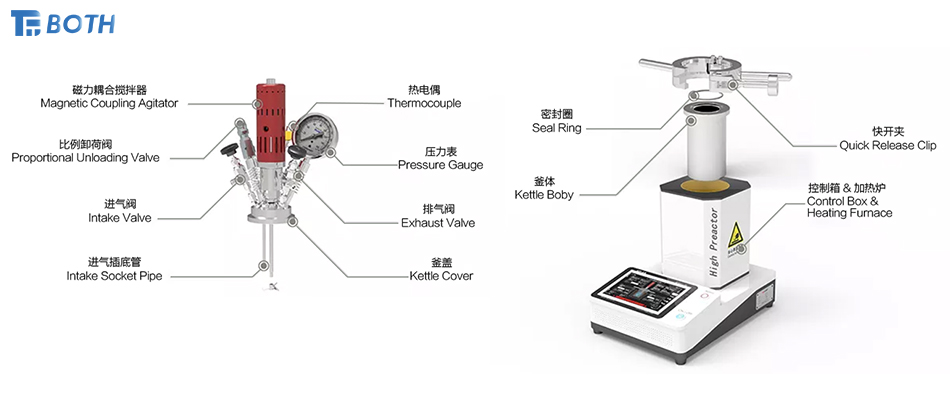

Ⅰ.Likarolo le Lisebelisoa

Ka moralo oa sebopeho le tlhophiso ea paramethara, mochini o futhumatsang motlakase o ka fihlella ho futhumatsa, ho tsoa mouoane, ho pholisa le ho kopanya ka lebelo le tlase ho hlokehang ke lits'ebetso tse ikhethileng. Ho itšetlehile ka litlhoko tsa khatello nakong ea karabelo, litlhoko tsa moralo oa sekepe sa khatello lia fapana. Tlhahiso e tlameha ho khomarela ka thata litekanyetso tse amehang, ho kenyeletsoa ts'ebetso, liteko le ts'ebetso ea liteko.

Li-reactors tsa khatello e phahameng li sebelisoa haholo liindastering tse kang petroleum, lik'hemik'hale, rabara, chefo e bolaeang likokoanyana, dae, meriana le lijo. Li sebetsa e le likepe tsa khatello bakeng sa lits'ebetso tse kang vulcanization, nitration, hydrogenation, alkylation, polymerization, le condensation.

Ⅱ.Mefuta ea ts'ebetso

Li-reactors tsa khatello e phahameng li ka aroloa ka li-batch le ts'ebetso e tsoelang pele. Hangata li na le lisebelisoa tse futhumatsang mocheso empa li ka kenyelletsa li-coil tse futhumatsang ka hare kapa li-heaters tsa mofuta oa baskete. Li-external circulation heat exchangers kapa reflux condensation heat exchangers le tsona ke likhetho. Ho kopanya ho ka finyelloa ka li-agitators tsa mechine kapa ka moea o bubble kapa likhase tse sa sebetseng. Li-reactor tsena li ts'ehetsa karabelo ea mokhahlelo oa mokelikeli, mokelikeli oa khase, ho kopana ha mokelikeli o tiileng, le mehato e meraro ea khase-solid-mokelikeli.

Ho laola mocheso oa karabelo ho bohlokoa ho qoba likotsi, haholo-holo karabelong e nang le litlamorao tse kholo tsa mocheso. Ts'ebetso ea sehlopha e batla e otlolohile, athe ts'ebetso e tsoelang pele e hloka ho nepahala le taolo e phahameng.

Ⅲ.Sebopeho sa Sebopeho

Li-reactor tse nang le khatello e phahameng hangata li na le 'mele, sekoaelo, sesebelisoa sa phetisetso, mochini o tsosang takatso le sesebelisoa se koalang.

'Mele oa Reactor le Sekoahelo:

Khetla e entsoe ka 'mele oa cylindrical, sekoahelo se ka holimo, le sekoahelo se ka tlaase. Sekoahelo se ka holimo se ka kenngoa ka ho toba 'meleng kapa sa kopanngoa ka li-flanges bakeng sa ho qhaqha habonolo. Sekoahelo se na le likoti, likoti, le li-nozzles tse fapaneng.

Sistimi ea ho ferekana:

Ka hare ho reactor, agitator e thusa ho kopanya ho ntlafatsa lebelo la karabelo, ho ntlafatsa phetisetso ea bongata, le ho ntlafatsa phetiso ea mocheso. Agitator e hokahane le sesebelisoa sa phetiso ka ho kopanya.

Mokhoa oa ho tiisa:

Sistimi ea ho tiisa ka har'a reactor e sebelisa mekhoa e matla ea ho tiisa, haholo-holo ho kenyelletsa ho paka litiiso le litiiso tsa mochini, ho netefatsa ho ts'epahala.

Ⅳ.Lisebelisoa le Boitsebiso bo Eketsehileng

Lisebelisoa tse tloaelehileng tse sebelisoang bakeng sa li-reactors tsa khatello e phahameng li kenyelletsa tšepe ea carbon-manganese, tšepe e sa hloekang, zirconium, le li-alloys tse thehiloeng ho nickel (mohlala, Hastelloy, Monel, Inconel), hammoho le lisebelisoa tse kopantsoeng. Khetho e itšetlehile ka litlhoko tse khethehileng tsa kopo.

Bakeng sa lintlha tse ling mabapi le li-micro-reactors tsa tekanyo ea laboratori leHighPthoba maikutloRlibapali, ikutloe u lokolohile hoCkopana le rona.

Nako ea poso: Jan-08-2025